Diesel Engine Business Division

Authorized and Genuine Part Sales Agency of Hanhwa Engine

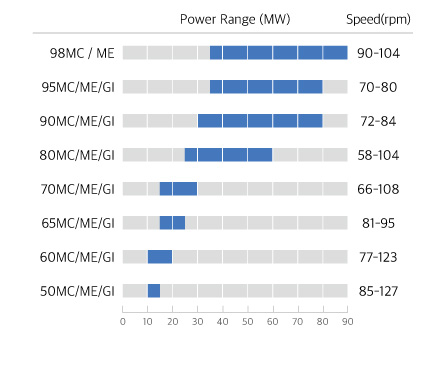

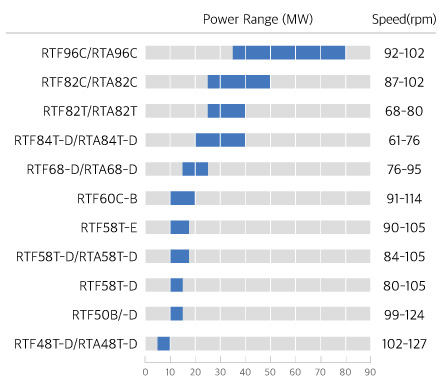

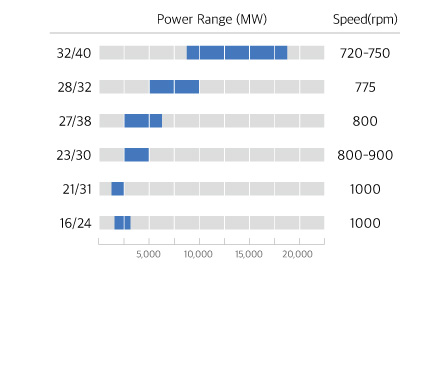

PRODUCTION RANGE

Hanhwa-MAN (2-Stroke)

Hanhwa-WinGD (2-Stroke)

Hanhwa-MAN DIESEL (4-Stroke)

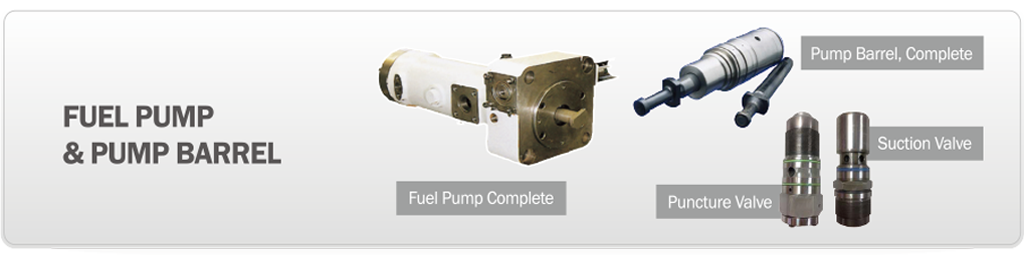

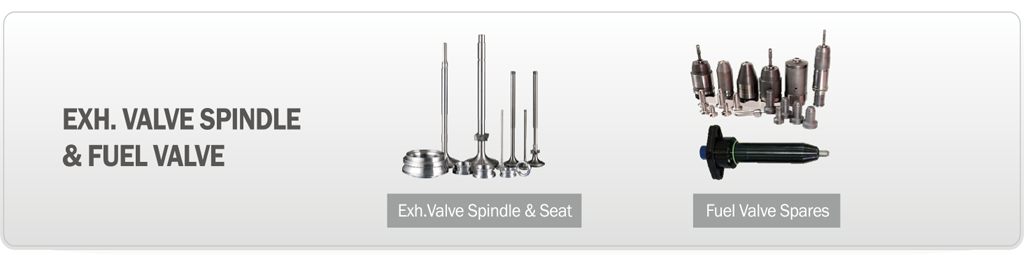

SPARE PARTS

2-stroke Engine Major Spare Parts

4-Stoke Engine Major Spare Parts

TECHNICAL SERVICE

TECHNICAL SERVICE 01

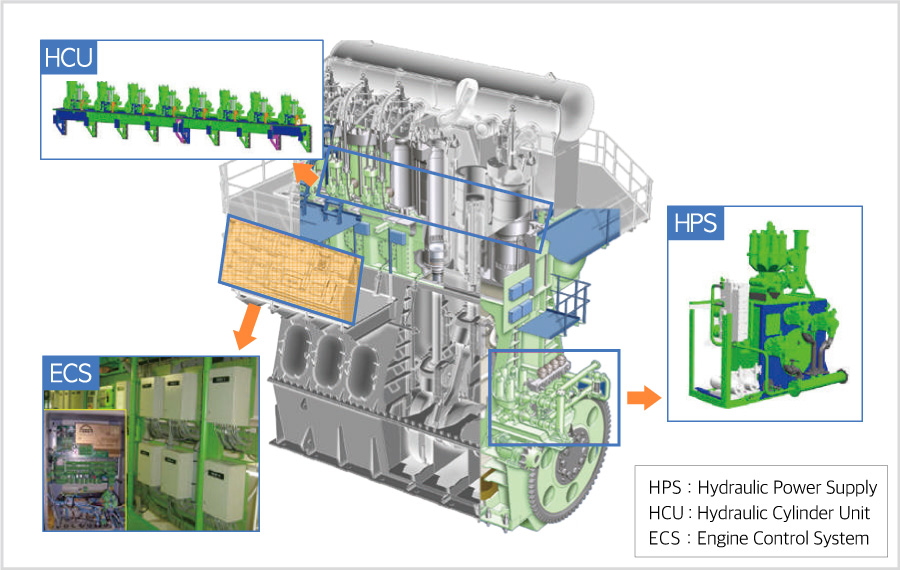

ELECTRONICALLY CONTROLLED ENGINE

– Main Components

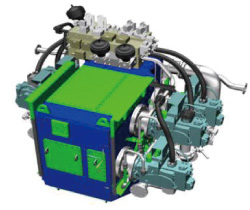

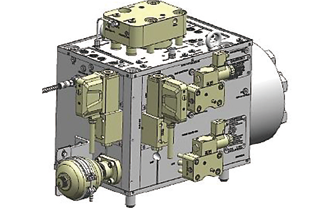

Hydraulic Power Supply

- Supply the necessary high-pressure hydraulic oil through driven pumps

- Consists of;

- – Engine driven pumps

- – Electrically driven pumps

- – Safety and accumulator block

- – Filter Unit and high pressure pipe

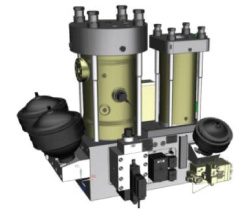

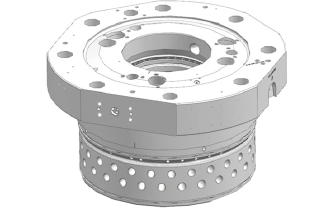

Hydraulic Cylinder Unit

- Deliver the hydraulic oil to each cylinder so as to actuate the fuel and exh. valve

- Consists of;

- – Hyd. Oil distribution block with FIVA valve

- – Fuel oil pressure booster with ELFI

- – Exhaust valve actuator with ELVA

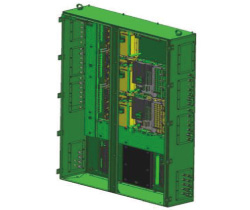

Engine Control System

- Human Machine Interface

- Engine Interface Control Unit

- Cylinder Control Unit

- – Alpha Cylinder Lubricator

- – Starting Air Valve

- Communication Network

- Auxiliary Control Unit

- Hydraulic Cylinder Unit

- Engine Control Unit

- Hydraulic Power Supply

- – Auxiliary Blower

- Tacho System

– Maintenance and Commissioning

1. HYDRAULIC CYLINDER UNIT

- · Fuel booster unit

- · Exhaust actuator

- · Accumulator

- · HPS P/P Recondition / Upgrade

(HS3->HS4) - · FIVA valve

- · Cylinder lubricator

- · Distributor block

2. HYDRAULIC POWER SUPPLY

- · Accumulator block

- · Hose & Compensator

- · Accumulator

- · Cartridge Valve

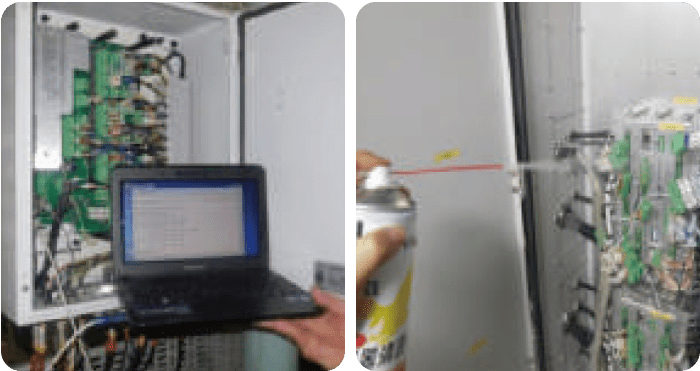

3. ELECTRIC COMPONENT

- · Electric control panel

- · MPC & MPC-10

- · Level switch

- · Cable and others

4. PNEUMATIC & CHAIN PART

- · Pneumatic system

- · Chain re-tighten

- · Guide bar

- · Main Starting Valve

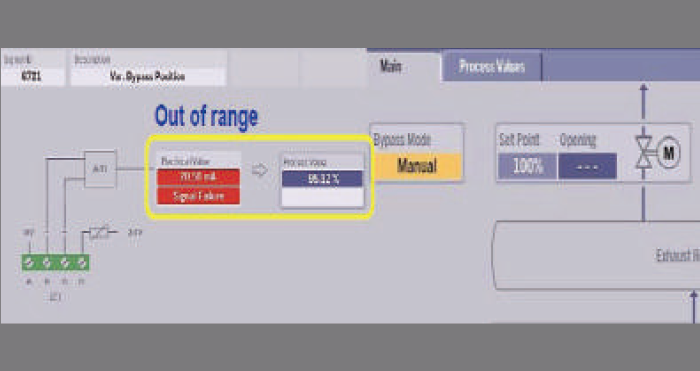

5. CALIBRATION & FUNCTION TEST

- · Inductive sensors

- · Swash plate positioner

- · Exhaust bypass system

- · Telegraph handle

- · Tacho system

- · Safety device

6. CONFIRM TRIAL

- · Engine starting test

- · Adjustment of fuel quality offset

- · Check of cylinder lubrication feed rate

- · M/E performance during confirm trial

TECHNICAL SERVICE 02

GAS INJ. ENGINE (ADDING ON ELECTORNIC. CONTROLLED ENGINE)

– Main Components

Gas Control Block

- Delivery the gas to each cylinders via control valves.

- Consists of;

- – Gas block

- – ELWI/ELGI valve

- – Window valve

- – Purge/blow off valve

- – Adapter block

- – Gas chain pipe

Cylinder Cover & Gas Injection Valve

- Combust gas fuel via GIV and make combustion chamber.

- Consists of;

- – Cylinder cover (Valve pocket, Cooling hole and etc.)

- – Gas injection valve

- – Fuel valve

- – Starting air valve

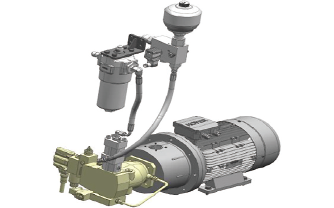

Sealing Oil Pump

- Prevent gas from entering the control oil system.

- Consists of;

- – Pump & motor

- – Non return valve

- – Proportional valve

- – Accumulator

- – Coupling

– Maintenance and Commissioning

1. GAS CONTROL BLOCK

- · Gas block

- · ELWI/ELGI valve

- · Window valve

- · Purge/blow off valve

- · Non return valve

- · Adapter block

- · Gas chain pipe

- · Accumulator

2. CYLINDER COVER & GIV

- · Recondition Cyl. Cover at workshop

(Welding & Lapping) - · Gas injection Valve

- · Sleeve & thrust collar

3. SEALING OIL PUMP

- · Non return valve

- · Proportional valve

- · Accumulator

- · Coupling

TECHNICAL SERVICE 03

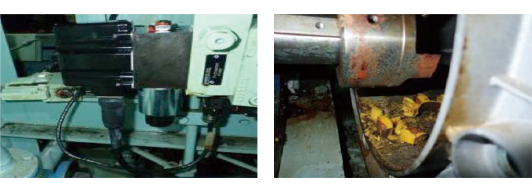

HPS PUMP EXCHANGESERVICE

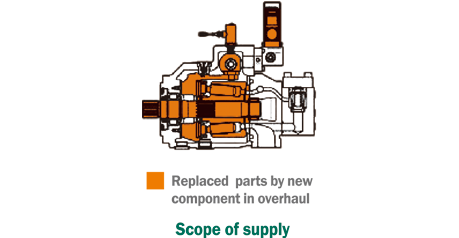

– This program is the full recondition of HPS pumps on exchange basis by maker supplied seed pump.

This solution addresses customer concerns about HPS pump maintenance, specifically long delivery times and the need for reliable service.

The reconditioning process replaces almost all components except the pump casing to improve quality, efficiency, and reliability at the original maker.

Reconditioned pumps will be supplied first. After installation, the old pumps will be returned to the original maker.

TECHNICAL SERVICE 04

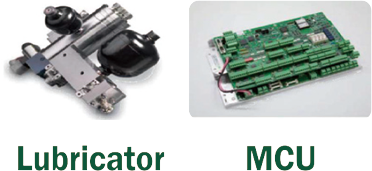

ALPHA LUBRICATOR/PNEUMATIC SYSTEM 5 YEARS MAINTENANCE PACKAGE

Based on our service experience and our guideline, the following parts must be replaced every 5 years or 32,000 R/H to ensure optimal and trouble free operation.

Recommendation Items

| ITEM LIST OF ALPHA LUBRICATOR MAINTENANCE | |

|---|---|

| Category of kits | Description |

| Service kit for alpha lubricator |

|

| Maintenance kit for alpha lubricator |

|

| Lubricator pump station service kit |

|

| Pressure filter element |

|

Recommendation Items

| ITEM LIST OF ALPHA LUBRICATOR MAINTENANCE | |

|---|---|

| Category of kits | Description |

| Service kit for pneumatic system |

|

| Recommended spare parts list as per engine type | |

TECHNICAL SERVICE 05

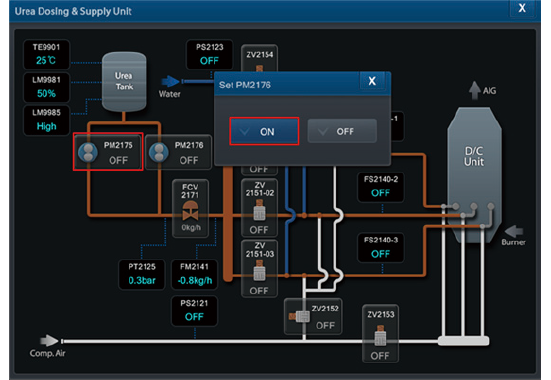

SCR ALL-IN-ONE SERVICE PACKAGE

– As the original designer of the DEL NOX SCR system, Hanwha Engine offers an all-in-one service, including comprehensive maintenance and annual spot check, to ensure customer convenience and satisfaction.

DEL NOX SCR MAINTENANCE SERVICE

- SCR system & flow sequence check

- Adjusting Urea dosing.

- NOx Sensor check

- Urea Nozzle check

- Valve & Flowmeter check

- Burner & Blower check

- Catalyst visual inspection

DEL NOX SCR ANNUAL NOX MEASUREMENT

- PURPOSE

- - Measurement & assessment of NOx reduction efficiency.

- METHOD

- - By qualified experts and reliable measuring device.

- OUTCOME

- - Documents for verification.

TECHNICAL SERVICE 06

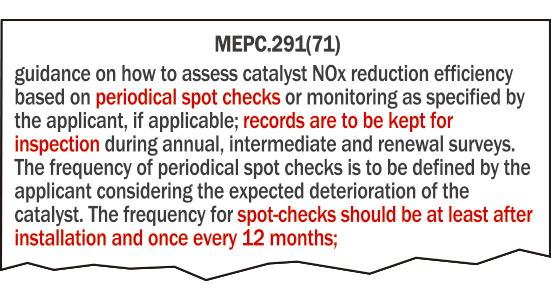

DEL NOX SCR CATALYST REPLACEMENT

– When catalyst to be replaced?

- Low NOx reduction efficiency

- Catalyst is to be replaced when period spot check result shows low NOx reduction efficiency.

- Serious damage on catalyst

- Serious damage reduces catalyst efficiency. This can be checked through visual inspection by experts.

– How to replace catalyst?

- Order new catalyst

- Transfer to replacement place

- Replace catalyst

- Dispose old catalyst

TECHNICAL SERVICE 07

MEASUTAL

– Measutal is the digital type deflection gauge for crank shaft.

- Make your Deflection Measurement Wirelessly.

- Be free from work Danger.

- Be quick in measurement.

TECHNICAL SERVICE 08

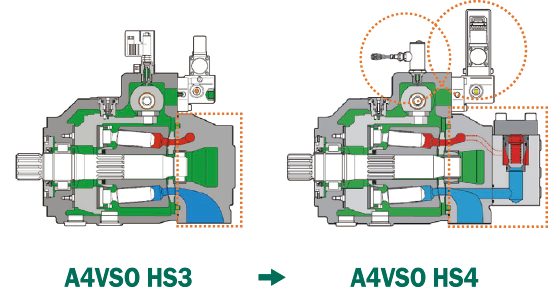

HPS PUMP UPGRADE BY EXCHANGE BASIS(HS3->HS4)

– This program is total solution for the full recondition of HPS pumps and upgrade of HS3 pump to HS4 pump with safety block, proportional valve and inductive sensor.

Since the production of HS3 Pump was

terminated in 2014, the customer should

replace HS3 pump to HS4 pump.

Recondition work is same as HPS pump

exchange service.

Fully reconditioned HS4 pumps will be

supplied to the vessel at first.

After replacement&upgrade HPS, system,

old HS3 pumps will be returned to the maker.

TECHNICAL SERVICE 09

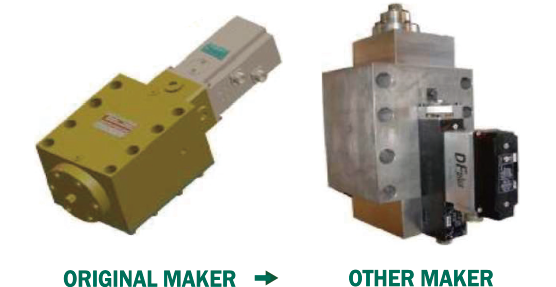

FIVA VALVE RETROFIT

– Due to various reasons, such as the original manufacturer's discontinuation or the need for improved performance, customers require retrofit service packages. We can offer both spare parts and service to meet these needs.

The service scope (If necessary)

- FIVA replacement to other maker

- Install the terminal boxes and the cable

- Update the parameter on ECS

- Commissioning

TECHNICAL SERVICE 10

ALPHA LUBRICATOR RETROFIT/UPGRADE SERVICE

– Alpha Lubricator Retrofit : Alpha Lubricator will optimize the consumption of cylinder oil.

– Alpha Lubricator Upgrade : Upgrade Alpha Lubricator with optimized consumption of cylinder oil at low load.

TECHNICAL SERVICE 11

RECONDITION OF ENGINE COMPONENT

– The following engine components can be reconditioned at maker authorized facility.

- Main engine : Piston Crown, Cylinder Cover, Exhaust Valve Spindle/Bottom Piece, FIVA Valve, ETC.

- Auxiliary engine : Cylinder Head, ETC.

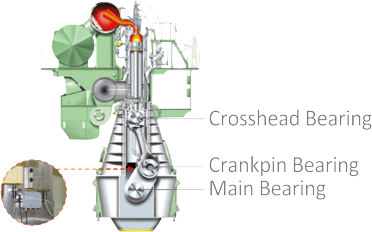

TECHNICAL SERVICE 12

O-WACS/B-WACS

– O-Wacs will monitor the water content of in L.O.

– B-Wacs will monitor the condition of three major bearings.

- O-Wacs& B-Wacs are the monitoring and alarm system for bearing and L.O.

TECHNICAL SERVICE 13

DRY-DOCK SUPERVISION SERVICE

Supervision Service

1 Supervisor

All of type for engine

Supervision Service details

01 Close inspection

incl. measuring

- Piston Component

- Bearing Condition

- Cylinder Liner

- Fuel Pump incl. Timing

- Exh. Valve

- HP Pipe

- Alpha Lubricator System

02 Visual Inspection

- Crank Case & Chain wheel

- Gas & Scav. Air Receiver

- Cam & Cam shaft

- Top Bracing

03 Instruction & Education for crew

- Job procedure

- Emergency Operation

- Finding root reason

- Trouble shooting

Benefit & Output Safety

Safety

- Engine operation

- Work

- Precaution